What is Pipe Socketing or Pipe belling?

Belling is that the method of heating the top of a PVC tube and increasing its diameter with help of mold.

The enlarged end is named a bell, socket, or the male-end. the opposite end is the spigot or the female.

Performance of the joint shaped between the spigot and bell is vital. You don’t wish groundwater or surrounding soil to infiltrate into the pipe. Water leakages should even be avoided.

Joints are strengthen using numerous techniques; an adhesive could also be applied or a seal may be put in within a grooved bell to form a seal with the spigot. You’ll perceive this more after we mention belling techniques.

Working Principle behind the Socketing process or belling process

There are different kinds of plastics: thermosetting plastics, which are irreversibly set and cannot be re-melted, and thermoplastics, which may be melted and re-formed.

Because PVC is a thermoplastic, you can still heat and expand the pipes after they’ve been cooled in the cooling bath.

Process of Socketing or Belling

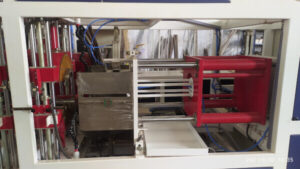

An extruder, shaping die, vacuum calibration tank, chilling bath, haul-off, and cutter are all part of the PVC manufacturing line.

At the finale, there is a belling machine. If you select an automatic belling machine, it will be installed online.

The pipes are automatically fed into the PVC belling equipment during the online belling operation.

A manual belling machine will require at least ONE OR TWO people to operate.

Types of Pipe Socketing Machine or Belling Machine

Plain Socketing Machine / Plain Belling Machine

-

- Plain Socketing is available in a variety of configurations, including semi-automatic, automatic, fully automatic, in line, Out line, Inline Servo, Rotary Indexing, Electrical Conduit, Conduit Flat Bed, Conduit Rotary, Rotary, Online, Offline, Repair Coupler, Linear Model, Elastomeric Ring Fit, RRJ socket, ESR, SWR, and more

SWR Socketing Machine / SWR Belling Machine

-

- SWR Socketing is also available in a wide range of variants, such as semi-automatic, automatic, fUlly automatic, in line, Out line, Inline Servo, Online, Offline, Repair Coupler, Linear Model, etc…

RR Socketing Machine (ESR Socketing Machine) / RR Belling Machine (ESR Belling Machine)

-

- Rubber Ring Socketing machine also known as Elastomeric Socketing machine.

- Rubber Ring Belling machine is also known as Elastomeric Belling machine.

- RR or ESR Socketing also comes with many options like semi-automatic, automatic, fully automatic, inline, Outline, Inline Servo, Online, Offline, Repair Coupler, Linear Model, Elastomeric Ringfit, RRJ socket, ESR, RR

Application industries of Socketing Machine or Belling Machine

Pipe socketing machine is designed for the PVC sewage pipes, water supply pipes, electric cables pipes, Agri pipe, solvent cement pipe, PVC pipe, UPVC pipe, PP Pipe, CPVC Pipe, PVC conduits automatic belling with U type, R or square type.

Parts of Socketing Machine or Belling Machine

Feeder device

-

- The frame supports the feeder apparatus, which pushes the pipe horizontally. Our feeder device is both stable and precise.

Heating

-

- In our PVC belling machine, we use electrical heaters.They use contact heating with an aluminium block to heat the pipe.

- This heat treatment process is very accurate as only the component that shapes the bell is heated.

- Infrared heating with short wave heaters is an alternate technique of heating. It is typically applied to smaller pipes.

- Depending on the level of softening required, a PVC pipe expanding machine can have multiple heating ovens.

- We simply need additional information about your products in order to recommend the quantity of heaters you’ll require.

Mould

-

- As previously said, there are several sorts of moulds. A plain mould is all that is required for U type belling.

- For R type bells, we employ a mechanical mould with collapsible and expanded inserts to make the groove. We may provide moulds in a variety of sizes that are easily interchangeable.

Cool water spray system

-

- We use flowing water to spray cold pipes after they have been formed. Water jets are installed on the belling station.

- Once the pipe has cooled, it cannot be easily altered. Alternatively, air can be blasted on the pipe’s surface to cool it.

Hydraulic components

-

- In order to move a mechanical element, hydraulic systems use an incompressible fluid to convey force from one place to another.

- The hydraulic components of the automatic belling machine include the cylinder used to grab the heated pipe in the belling station.

- The hydraulic system is also used to move the mould.

Electrical components

-

- The major electrical components of the belling machine are the PLC-controlled control components and the power supply.

- There is a Siemens panel/touch screen that allows you to access and present all machine controls so that it can work automatically.

Advantages of our PVC pipe belling machine or Socketing Machine

- If you choose our belling machine for PVC pipe socketing, you will receive the following benefits:

- It consumes less energy, which reduces your power bill and running costs.

- We include parts from well-known international brands.

- It is capable of producing two belling styles on a single machine. The “U” and “R” styles.

- The automatic belling machine can be integrated into a production line or utilised independently.

- We offer a wide range of mould sizes ranging from OD 20mm to 630mm.

- With a multiple languages touch screen, learning how to programme the machine is easy, resulting in less time spent teaching the operator.

- Our pipe belling machine is made of high-quality materials and uses cutting-edge technology.

- Even after many years of use, it is still in good condition.

- The belling machine has a solid frame made of cold-drawn steel pipes welded together.

- We can readily design the machine to meet your individual needs; for example, we may supply the PVC four pipe belling machine.

What is the socketing or belling machine price?

- The price is determined by the model you intend to purchase. The quantity of units ordered per order may have an impact on the buying price.

- The R type pipe expanding machine is also more expensive than the conventional socket U type equipment. Similarly, an automatic belling machine is more expensive than a manual one.

- The machines typically cost between $8,000 and $20,000 USD. If you want to buy a new belling machine online at the lowest price in Ahmedabad, Gujarat, India, please contact us and tell us about your needs.

- We will provide you with the finest possible combination of durability, performance, dependability, and value.