Pipe Belling Machine

Pipe Socketing Machine

PVC pipes need to be joined along after they are installed. There are many connection ways as well as solvent-cement additionally the} belling/socketing process.

The most affordable and quickest method is that the belling process. For these reasons, it’s the foremost standard joining method.

At Candour Machinery, up to eighty % of consumers who purchase PVC pipe production lines, also purchase a belling machine. It’s straightforward since the machine is simply integrated into most lines, and the customers save energy & time.

However, if you’re searching for pipe socketing machine manufacturers, you’re in the right place.

We’ll share our data on belling techniques. The options of our automatic belling machine also will be covered.

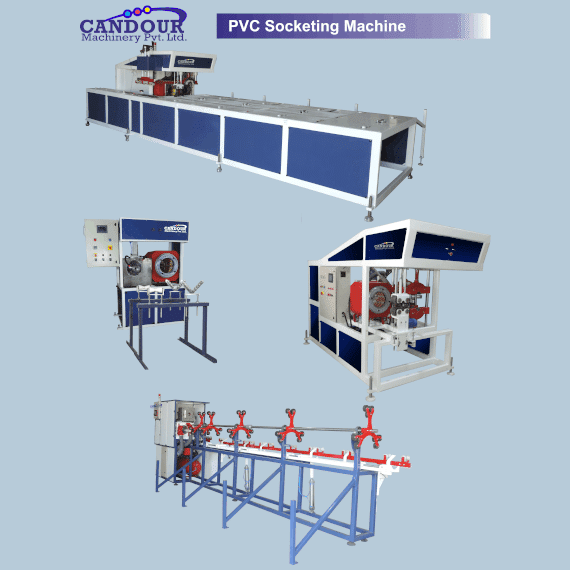

Candour Pipe Socketing Machine or Pipe Belling Machine

PVC pipe socketing machine is built for the PVC sewage pipes, ground water pipes, electrical cable pipes, and PVC conduits automatic belling with U, R, or square type.

The PVC pipe belling machine process is fully automated, from pipe sending to operational tables, pipe heating, pipe belling, and pipe discharge. All of this is managed by a PLC system, and the heating duration and belling processing will be tailored to the formulation’s specific circumstances and factory conditions.

PVC pipe socketing machine is equipped with a suitable mould that can automatically bell the plastic PVC pipe into U type, R type, or square type socket.

A socket is an opening or chamber into which another piece is designed to fit. A socketed pipe is one that has an expansion at one end to fit the end of a connection pipe.

A socketing / belling machine is a machine designed to produce a socket in a pipe.

To soften the pipe, one end is inserted into a compact heater. With the help of a mandrel, the pipe end is softened and given the desired shape.

Heating by infrared IR uniform pipe heating, resulting in even expansion and, as a result, a high-quality socket. Furthermore, the heating is much faster than other types of heating, resulting in increased production.

Candour Machinery manufactures one of the fastest automatic socketing machines on the market. We offer several machines based on our customers’ production capacity. These machines can make socket PP and PVC pipes with diameters ranging from 20mm to 400mm. We design and build belling equipment for Plastic and PP building sewage and pressure pipes. The machine is operated using a touch screen and a PLC.

We have designed a specific internal heating system utilizing infrared heaters, which allows us to reduce the machine’s power usage. Furthermore, inferred heaters can provide undiversified or uniform heat within the pipe. Candour belling machines utilize a hydraulic system for pipe socketing.

Features

- The machine is strengthened by a heavy structured frame created with square pipes.

- The system is entirely automated and controlled by a plc.

- Includes advanced safety options limit switches and in-built sensor coding.

- All electrical items and mechanical components are of the highest quality.

- The equipment frame is made of cold drawn rectangle steel tubing, which has a fine structure and is stable when the machine is running.

- The heating chamber uses a force-balanced circle air flue design that heats quickly and evenly; the pipe rotates positive and negative, reducing energy consumption.

- High automatic level, plc touch screen control, all operations are pre-programmed, the machine operates automatically

- The touch screen is made by delta, the contactors are made by siemens, and the photoelectric is made by atomics. Electrical elements adopt famous brands,

- Uses water cooling and out pressure shaping for water system pipes to maintain proper pipe socket shape.

- Reliable and precise

- Almost null maintenance

- Long pipe holding tray with simple bearing movement

- Easy detachment and assembly arrangements

- High-quality pneumatic cylinder

- High-quality solenoid valve

- Electronic temperature controller

- Circuit breaker protection

- Can be used on any length of pipe

- In-built IR heaters of 6500 w

- Heavy-duty brass pressure control valve

- Brass nipple with high rated pressure pipe

- Mandrel and 75mm and 110mm dies are included in the machine.

- Operation by one non / semi skilled operator.

Socketing machine or belling machine principle of construction

Conveying Unit

-

- Vibration-free pipe conveying

- Completely secured conveying system

- No hydraulic devices in the conveying system

- Stainless steel or coated metals are used

Heating system

-

- There is a significant reduction in heating time due to the new infrared rays entering deep into the material, which boosts the socketing capacity.

- The heat applied to the pipes distributes evenly and softly while also protecting the material. Furthermore, as the temperature rises,

- Any thermal damage that might occur is prevented because the heat is transmitted uniformly.

- Because our automatic socket machine, which is equipped with the AWI Plus, requires less heating time, the entire process may be performed with just one or two heaters, whereas the traditional approach would require two or three heaters.

- Another essential feature of our machine is that the new heater allows it to be turned on just when the tube is being treated, saving a significant amount of energy.

Forming Unit

-

- Transparent and easily accessible

- Tool swapping is simple and quick.

- Transparent and quick-to-open safety device

- maintenance-free tool carriage movement in two centrical guiding bars

- a complete process segment for simple inspection and access

- Maintenance-free fastening system with a tough design

- Because of the open top design, changing tools is simple and quick.

Control Panel

-

- DELTA display device

Switch Cabinet

-

- DELTA PLC satisfying the requirements of space

Tools

-

- enhancing the core tool

- blowing tool

Pipe socketing or belling styles

“U” type Socketing or Belling Style

-

- The pipe is heated before being inserted into a basic socket mould with a slightly wider diameter.

- PVC pressure pipes with ODs of 16mm, 20mm, 25mm, 32mm, 40mm, and 50mm are U-belling.

- An adhesive could be used to reinforce the bond during jointing.

“R” type Socketing or Belling Style

-

- can you notice, some differences are there in U-belling type. The inside of the bell has a groove. Following that, you might notice a black gasket.

- Gaskets made of synthetic or natural rubber improve the sealing capacity of the pipe. Typically, the gasket is fitted separately.

- For pipes with an OD ranging from 63mm to 630mm, R type belling is used.

- The pipes can be joined without the need for glue. Until the reference mark is achieved, the spigot end is lubricated and pushed into the bell. The lubricant must be water soluble and not impair the functioning of the gasket.

“Square” type Socketing or Belling Style

-

- The square type is a PVC belling style that is comparable to R-belling. However, instead of being asymmetrical, the groove is rectangular.

“J” type Socketing or Belling Style

-

- J Type sockets The belling scope is for 20 mm to 1000 mm pipe diameter.